Why choose pallet racking?

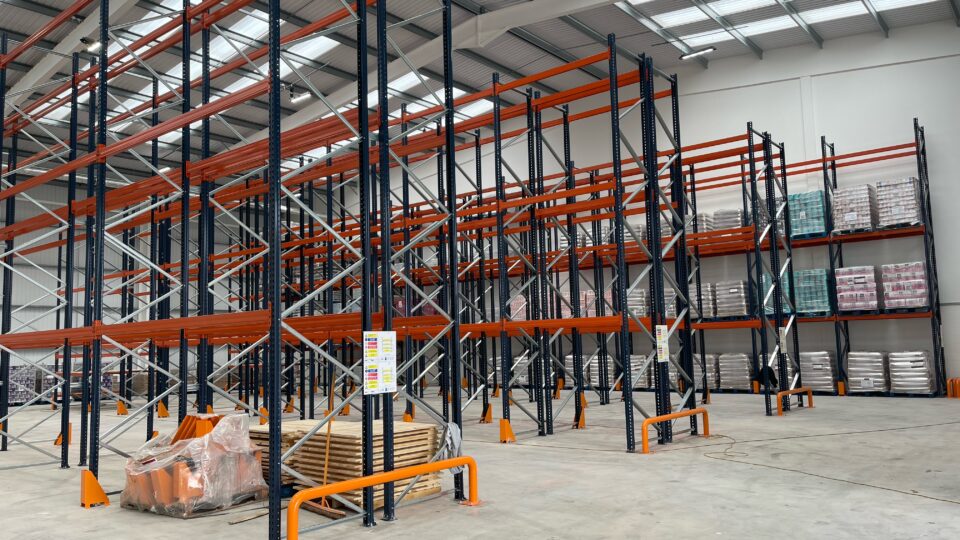

- Pallet racking, also known as a pallet racking system, is an excellent solution for businesses looking for efficiency and organisation in their storage spaces. Widely employed in industrial and warehouse settings, and offers a systematic approach to storage needs.

- Allows businesses to make the most of their storage space with pallet racking. By vertically stacking pallets, businesses can increase inventory storage within the same workspace, allowing quick loading and unloading of pallets from storage bays using forklifts and other lifting equipment.

- Offering diverse configurations, a warehouse pallet racking system enhances accessibility by minimising required floor space through dense vertical storage options such as push-back racking. This flexibility allows businesses to choose the best solution for their business requirements.

- We supply high-quality pallet racking systems to withstand wear, pressure and damage without losing its effectiveness or quality. Constructed from robust materials such as Steel, they offer outstanding durability and longevity ensuring reliable performance long term. This results in savings for businesses from reduced maintenance and replacement costs.

- Offering scalability, a pallet racking system enables businesses to expand their system as they grow. It’s ideal for establishing a well-organised, safe, and tidy storage space for your business. To learn more about how pallet racking can benefit your business. Call our experts today on 0800 027 1966.

Pallet Racking from NSI

Are you looking for a bespoke solution tailored for your business? We have a wide range of pallet racking to choose from in various sizes. These include: heavy-duty, modular and adjustable pallet racking ideal for use in industrial and warehouse spaces.

Getting the basics right for any racking project is crucial for every racking project, and that’s precisely what we focus on when designing a customised solution for your business. We can liaise with your team and forklift supplier, perform a thorough analysis of your operations to determine the most suitable industrial pallet racking system for your business needs.

Our pallet racking systems include:

• Wide aisle pallet racking.

• Narrow aisle racking.

• Cantilever racking.

• Pallet live and push back racking.

• Drive-in racking.

• Anti-collapse and racking mesh for all your safety needs.

Due to the special care that needs to be taken in the component selection, design and industrial pallet racking installation. Our specialist team will work closely with your business to ensure you achieve the perfect warehouse setup tailored to your needs and the specification of your building.

We Are SEMA Approved

We have been awarded a Highly Commended Status by the Storage Equipment Manufacturers Association (SEMA).We only use SEIRS qualified installation teams and ensure that all products and systems designs conform to the SEMA quality programme.

Why Use NSI Projects?

NSI Projects, a trusted supplier, brings over 40 years of experience in delivering cost-effective pallet racking solutions to businesses across the warehouse and industrial sectors throughout the UK.

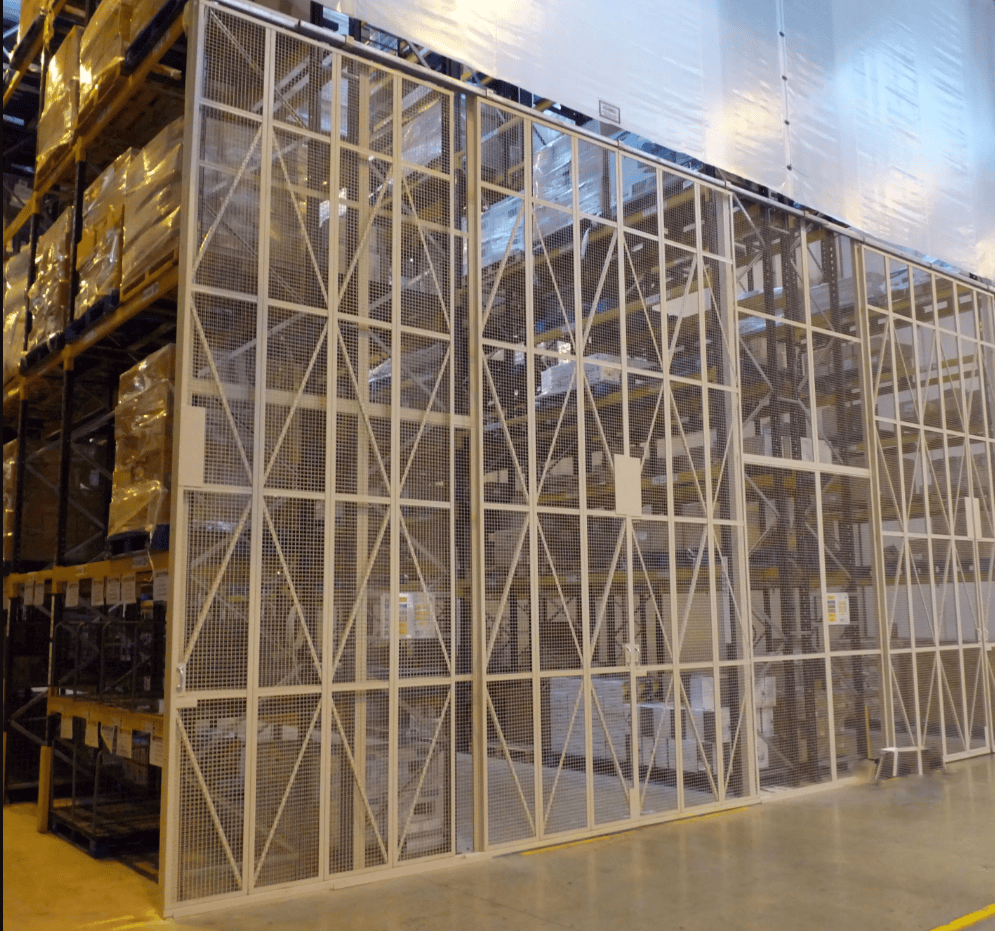

Aerosol and Explosives Cages

NSI can design and install all types of aerosol storage cages to satisfy Insurance Company and Building Control/Fire Officer requirements.

Shuttle Racking System

For clients for whom ultra-high density pallet storage is important, a shuttle racking system can be the answer. The concept is based around the fact that the forklift never enters the racking, individual pallet movements being conducted on intelligent RF guided shuttles that operate on rails millimetres below each pallet.

Pallet Racking Repairs

NSI undertake all types of pallet racking repairs for a number of national companies across their portfolios, as part of a holistic system of rack safety.

Racking Inspections

Racking Inspections are integral for rack safety. They are undertaken by our SARI qualified inspector to maintain H&S standards.