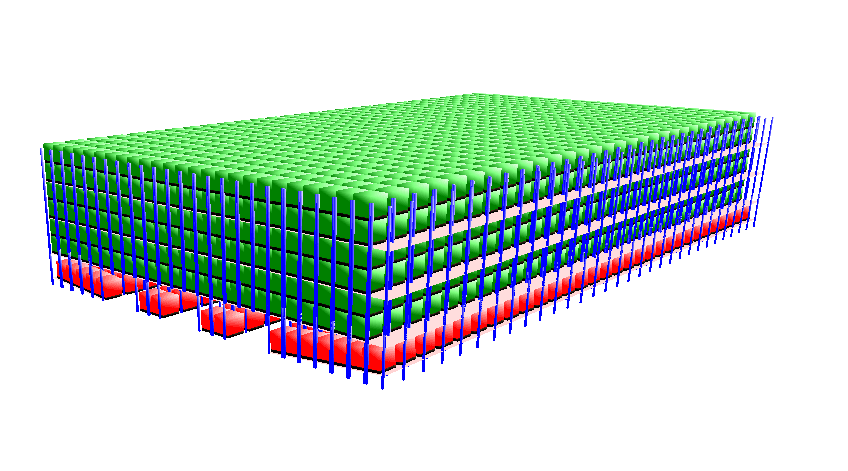

Ultra-High-Density Pallet Storage

Although similar in structure to drive-in and pallet live systems, shuttle racking is worlds apart with regard to its functionality, speed and control.

The concept is based around the fact that the forklift never enters the racking. Individual pallet movements are made by intelligent RF guided shuttles that operate on rails millimetres below each pallet.

Once the shuttle had been deposited by the forklift in a lane, it works autonomously without further intervention until it has finished its programmed tasks. Communications are by RF or WIFI, with programmable software interfaces.

The shuttle lifts the pallet on a smooth hydraulic lifting system, with jerk-free movement. It detects the pallet using lasers, positions itself under the pallet, lifts the pallet clear of its holding rails by just a few millimetres and then performs the required task, depositing the pallet gently where required.

Let us work with you to build a business case bespoke to your operation.

The Business Case for Shuttle Racking

- Considerable density of pallets can be achieved by the removal of conventional racking aisles.

- Shuttle movements can substantially reduce the number of forklift trucks needed for an equivalent number of pallet movements.

- Every pallet face can be accessed individually, from both sides of the block if required.

- There is virtually no limit to the length of runs that can be achieved, only the required speed and access to goods limit the run length.

- The block can be operated FIFO (i.e. fed one side, taken the other) or LIFO (put and pick from the same face) or both FIFO/LIFO. No other system offers you this type of flexibility or future-proofing with regards to configuration.

- Considerably less damage to the rack with reduced FLT movements.

- Fewer aisles to manage MHE/personnel safety issues within.

Design Constraints and Concepts

There are really no limits other than your building size and MHE capability on the width, size and height of a block of shuttle racking system.

This high-density, pallet storage system can handle heavy pallets up to 2 tonnes, and pallets stacked 2 high, if safe to do so, as movements are horizontal and stable, thus potentially halving pallet movements within the system.

Shuttle Racking System over Pick Operation

Shuttles can be configured to operate above an existing pick operation, thus maintaining pick footprint while using the overhead volume as super-dense storage.

NSI understand that such installations tend to represent a considerable investment. You need a committed partner who will work with you to develop the right design and robust business case for capital approval. NSI are that partner. Call us for a free initial consultation.

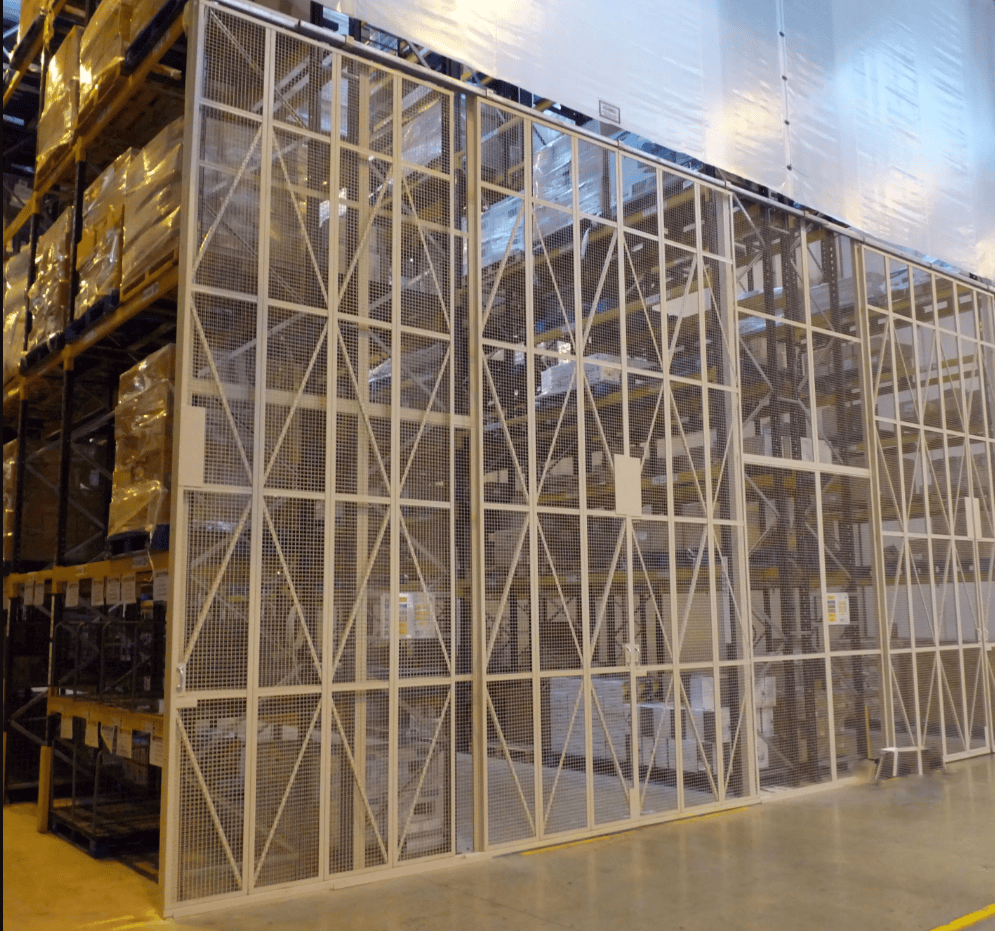

Aerosol and Explosives Cages

NSI can design and install all types of aerosol storage cages to satisfy Insurance Company and Building Control/Fire Officer requirements.

Packing Racking Repairs

NSI undertake all types of pallet racking repairs for a number of national companies across their portfolios, as part of a holistic system of rack safety.

Racking Inspections

Racking Inspections are integral for rack safety. They are undertaken by our SARI qualified inspector to maintain H&S standards.